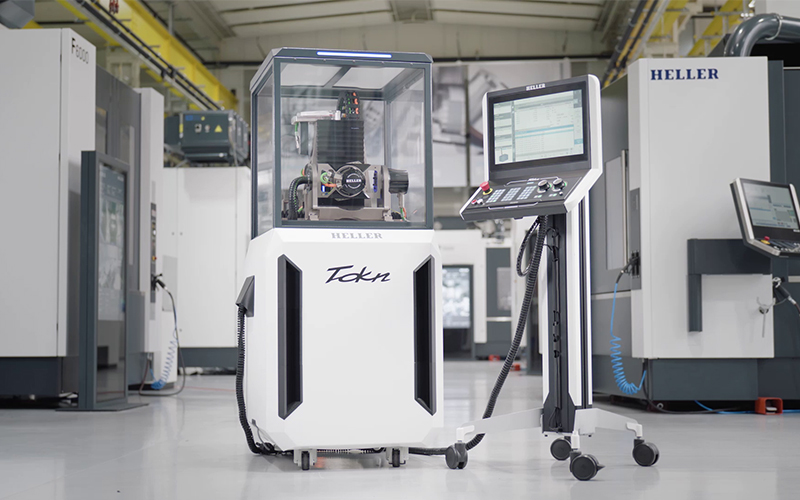

Thermal growth correction AutoLin

Productivity

| Precision

Using AutoLin, a quick measurement in X, Y, and Z is performed with the workpiece touch probe, and the thermal displacement of the machine’s structural components in the direction of the linear axes is recorded.

Characteristics

- This measurement is carried out on a ball that is permanently fixed to the rotary table carrier. The measured position is compared with a stored reference position, and the displacement is corrected by adjusting the reference points. The ball diameter is determined. If the results are not plausible, the measurement is repeated up to four times. After five implausible measurements, an error message is issued.

- The measurement must be initiated by the machine operator each time, e.g., based on the room temperature sensor’s notification.

- The reference position must be re-determined after performing AutoCal.

Benefits

- Correction of the thermal displacement between the spindle and the pallet.

Requirements

- Only in conjunction with a receiver for measuring probes (not included in the retrofit package).

- A probe tip of at least 100 mm length is necessary for the measurement.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!