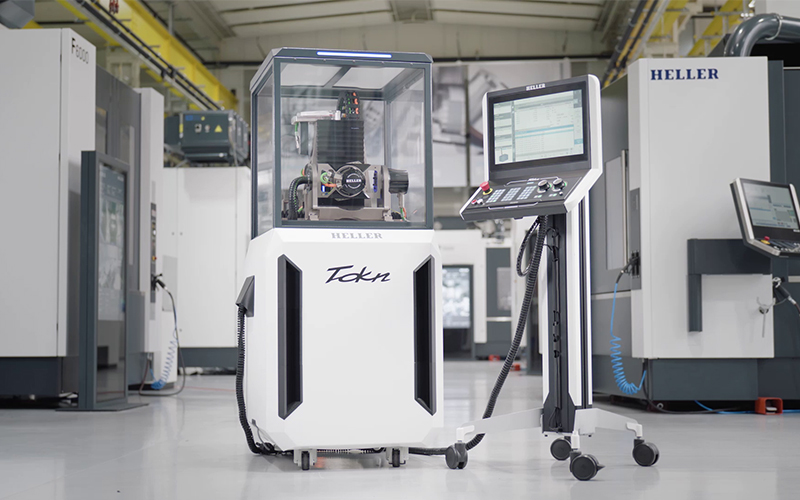

RENISHAW measuring probe

Productivity

| Precision

Quality assurance in the production process saves on complex and protracted correction cycles, as it indicates errors directly where they occur. The RENISHAW measuring probe checks the workpieces while they are still in the work area for precise machining and transfers the measured values to the control system for correction.

Characteristics

- Measuring of bores and surfaces with subsequent automatic compensation in the control (zero offset, tool compensations)

- Detection of impermissible preconditions (e.g. hole not present)

- Recording the measurement and position tolerances of the workpiece

- Available in infrared or radio technology

- OMP60 = Infrared measuring probe with standard accuracy

- OMP600 = High-precision infrared measuring probe

- RMP60-Q = Wireless measuring probe with standard accuracy

- RMP60-QE = Wireless measuring probe with standard accuracy

- RMP600-QE = High-precision wireless measuring probe

- Multidirectional

- Touch probing from all directions, without orienting the spindle

- Complete case

- with measuring probe, probe insert, tool holder, coolant pipe

Benefits

- More process reliability: no lengthy process interruptions due to complex troubleshooting, continuous quality control

- More machine safety: machine safety for unmanned production

- More precision: direct error detection and automatic correction

Requirements

- Renishaw measuring probe interface

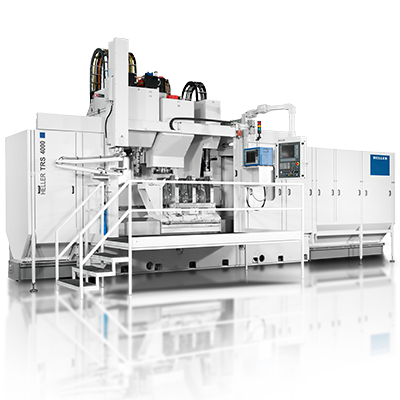

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!