Interpolation turning IPT

Productivity

| NC Technology

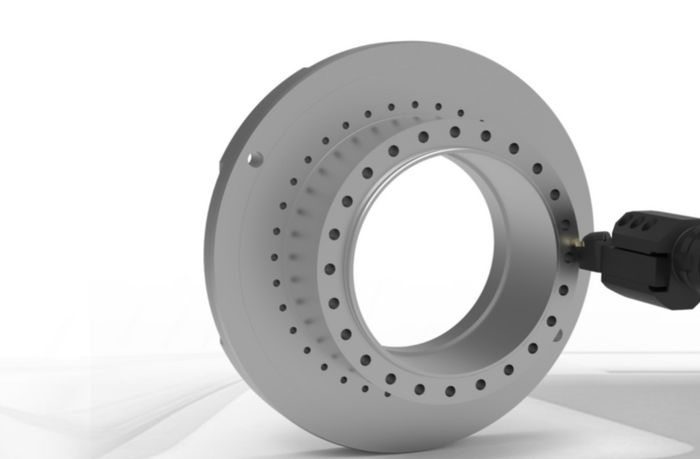

Interpolation turning allows rotationally symmetrical internal and external contours to be produced flexibly and easily using the turning process. Turning is carried out by interpolating the linear axes. The spindle is tracked in such a way that the tool is always positioned orthogonally to the workpiece surface. Conventional turning tools can be used for machining. Interpolation turning is based on the TRAINT transformation and is activated with the CYCLE 806 cycle with graphical support. The contours and machining are programmed conveniently using the Siemens turning cycles included in the package. The function is available for 4-axis and 5-axis machines. Machining is possible in the basic orientation of the machine as well as in the inclined coordinate system.

Benefits

- Flexibility: It enables the machining of complex geometries and symmetrical features on asymmetrical parts. Reduced tool costs: As fewer specialized tools are required, tool costs can be reduced.

- Less set-up time: Machining can often be performed in a single set-up, reducing set-up times and increasing productivity.

- Greater precision: Interpolation improves the quality of machining and ensures consistent tool movement.

- Versatile: It can be used on different types of machines.

Requirements

- Interpolation rotation option is possible from Giv 4.95 SP2

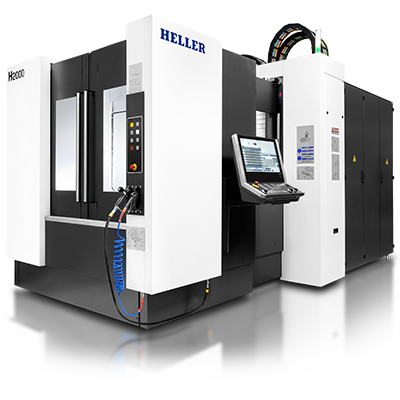

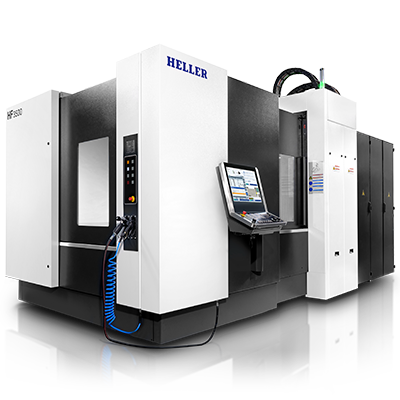

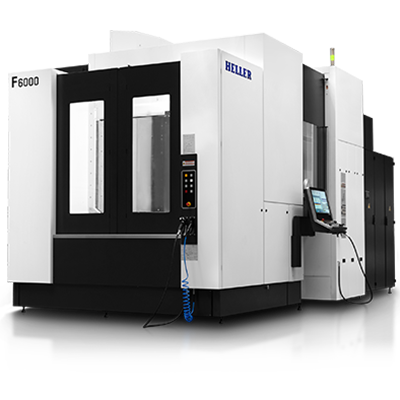

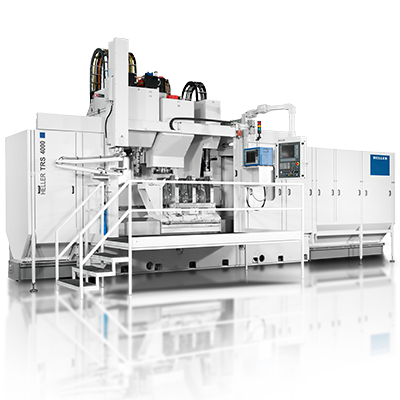

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!