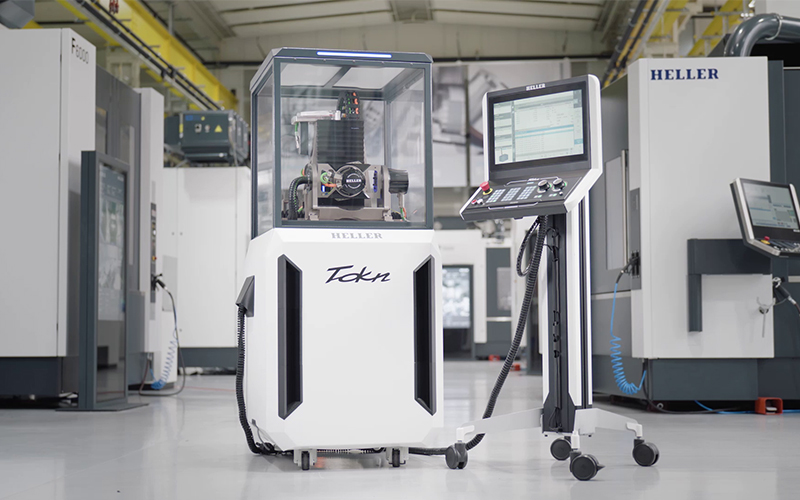

Integrated Tool Monitoring (IPM)

Availability

| Digitalization

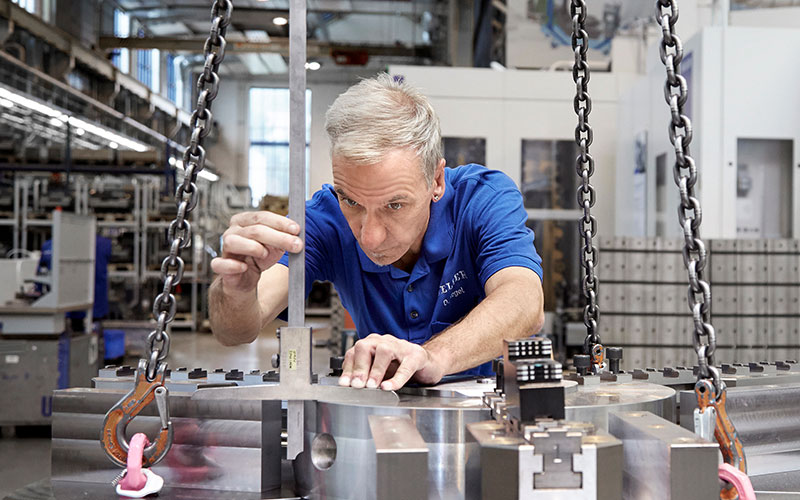

In unmanned shift operation, but also in normal production routines involving operators, automatic tool monitoring not only prevents expensive damage, but also unnecessary spoilage.

Characteristics

- Monitoring of tool breakage and overload during the machining process

- Evaluation of process signals from the digital drives, no additional sensors required

- Assignment of various monitoring processes (e.g. fixed limit, travelling threshold) and responses per tool

- Complete integration of basic monitoring in the Sinumerik 840D user interface, incl. machine preparation

Benefits

- More process reliability: complete monitoring and data for each tool current at all times

- Fewer unplanned failures, fewer downtimes: proactive and controlled tool replacement

- Lower costs: no expensive response to tool breakage and machine protected against overload

Requirements

- SIEMENS Powerline

- SIEMENS Solutionline

- Tools with the appropriate power and torque input, i.e. drilling from a depth of approx. 6-8 mm depending on the main spindle type and the machining process

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!