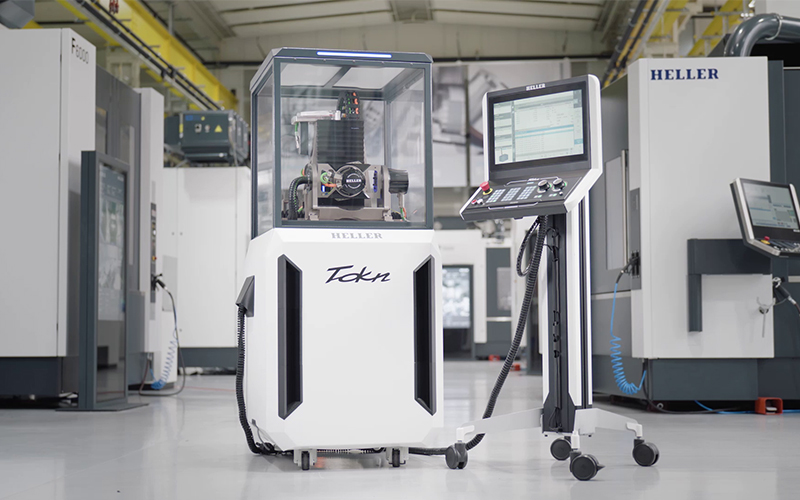

In-process tool breakage monitoring

Productivity

| Process Reliability

The in-process tool breakage monitoring (SBBK) function prevents a damaged tool from being used for the rest of the machining process and protects the downstream tool from consequential damage.

Characteristics

- Tactile system approaches tool tip on the magazine provisioning place

- For the tool change, in-process check without time loss

- For single spindle, coaxial tools (drills) with diameter of 1 - 6 mm, tool breakage is detected from 5 mm break, peak angle > 118° and minimum tool length of 70 mm at maximum tool length of 600 mm or minimum tool length of 270 mm at maximum tool length of 800 mm

- Angular drill heads and drill heads cannot be checked

Benefits

- Not time lost: check during tool change

- Lower costs: fewer rejects, fewer failures, less consequential damage

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!