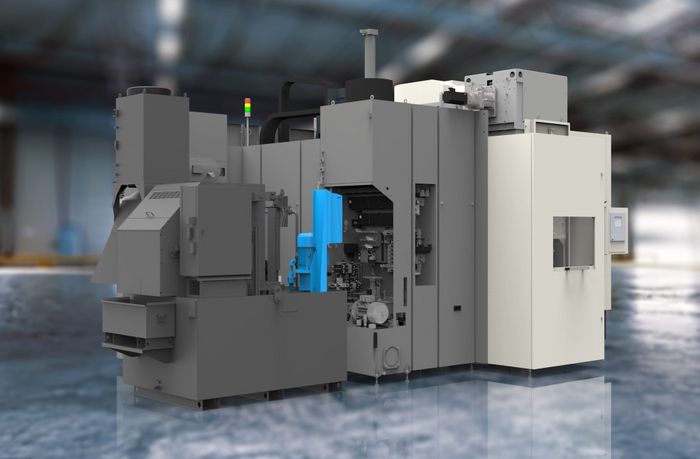

BLUE Coolant

Sustainability

| Energy Efficiency

Via intelligent control of the high-pressure coolant pump, BLUE Coolant allows you to save energy in a sustainable manner for a significant reduction in operating costs – without any compromise.

Characteristics

- Control of high pressure pump with frequency converter

- Direct adjustment of the high pressure coolant pump's volume flow and hence the energy consumption to the machining task concerned

- Motor and pump are retained

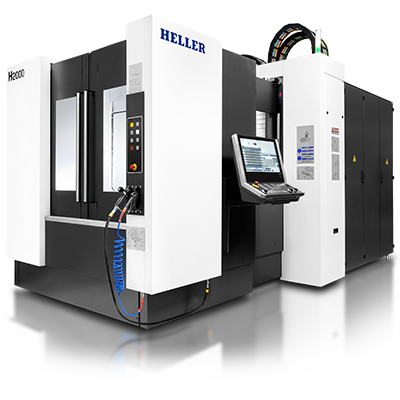

- Compared to the standard high-pressure coolant pump:_ Energy savings per year (exemplarily for H2000 Gen.2): -7,200 kWh*

- CO2 savings per year (exemplarily for H2000 Gen.2): -3,125 kg CO2*

- * = Assumption energy statuses per day - STANDBY 4h, OPERATIONAL 4h, WORKING (with maximum cooling capacity in spindle warm-up) 16h. Energy statuses pursuant to VDMA form 34179, carbon emission according to the current fuel mix in Germany 434 g/kWh, with 250 working days per year

Benefits

- Up to approx. 70% energy savings depending on the machining process, compared to a system without frequency control

- Process-adapted speed results in lower noise level

- Longer service life of the high-pressure coolant pump

- Reduction of long-term maintenance costs

- Potential additional savings with use of coolant cooling

Requirements

- Coolant unit (manufacturer KNOLL)

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!