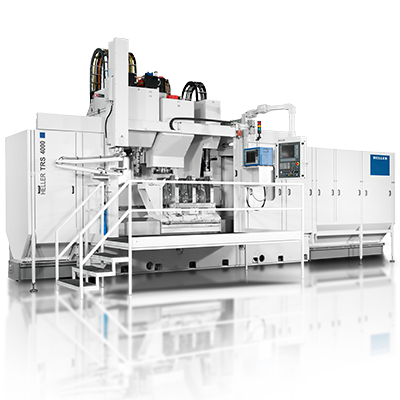

VKM 5-axis machining centres

Series production of structural components

A vertical machining centre with high dynamics and stability, long traversing paths and yet highly accurate machining results – at first, this sounds like a contradiction in terms. Our VKM 5-axis machining centres is the perfect reconciliation of these apparent opposites.

- agile, vertical 5-axis machining centre for the flexible complete machining of structural components in series lightweight construction

- long traversing paths

- translational axes in the tool, rotative axes in the workpiece

- directly driven rotary axes

- machine basic body as a stable, self-supporting and vibration-damping cube in a steel shell design, filled with vibration-damping material

- low, easily movable kinetic masses for high speeds along steep acceleration ramps

- access to the work area from two opposite sides

- optimum chip flow

- prepared for minimum quantity lubrication

- tool change via pickup

- simple automation thanks to a high degree of standardisation

- ready for Industry 4.0: intuitive touchscreen control, evaluation and visualisation of process data, e-maintenance

VKM 2: two spindles, two stand-alone centres.Integration of two stand-alone VKM 5-axis machining centres in the same basic body for optimum loading and unloading in material flow-optimised layouts.

Downloads

At a glance, our Download Centre offers an extensive range of information materials about our company, our products and services for you to download.

Further information can be found at: august-wenzler.de/en/vkm

VPM 5-axis machining centres

Series production of vehicle body components

Body components can vary enormously in size, your machining centre should be equally adaptable. Because the traversing paths of our vertical VPM 5-axis machining centres are scaleable, they can be completely flexible in their reaction to your project requirements. A swivel head can be used in addition, depending on the machining concept.

- two configuration options:single-spindle (decoupled pendulum machining with one machining spindle), or two-spindle (machining with direct loading and two machining spindles)

- series loading and unloading of both spindles

- loading and unloading by robot, gantry and operator

- space-saving construction in the value stream direction

- easily accessible

Downloads

At a glance, our Download Centre offers an extensive range of information materials about our company, our products and services for you to download.

Further information can be found at: august-wenzler.de/en/vpm

Contact

Contact

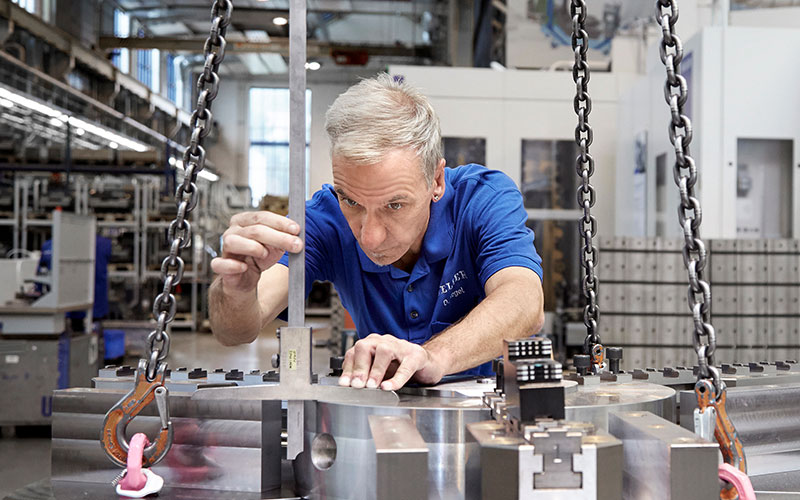

Sales & Services

Do you have questions about our products and services? Please get in touch with us, we are here for you! Benefit from our global HELLER network with knowledgeable sales and service contacts located in your region.

Find your nearest personal contact.

No results could be found.

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!