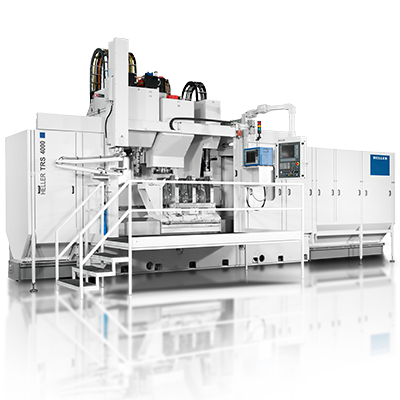

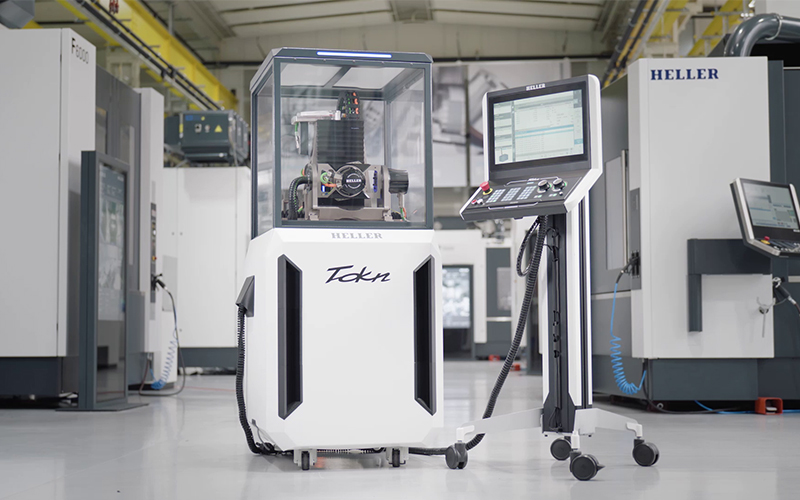

Interface for robot loading

Productivity

| Process Optimisation

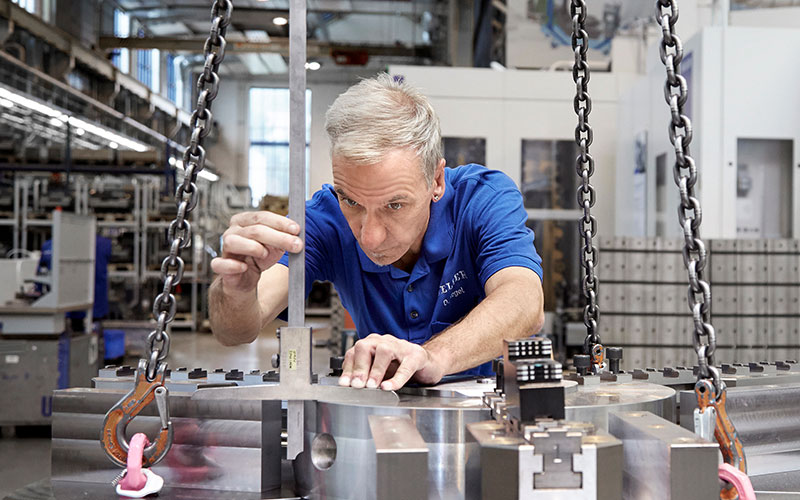

Manual loading and unloading is time-consuming, expensive and can be a source of errors. With the interface for robot loading at the workpiece setting station the machine can be integrated into an automation system. With the automatic loading/unloading sequence, you save time and gain process reliability.

Characteristics

- During the automatic de-setting sequence the workpiece on the workpiece setting station is unloading by the integrated automation

- During the automatic setting sequence the workpiece on the workpiece setting station is loading by the integrated automation

Benefits

- Shorter setting and de-setting times: automated sequence significantly reduces setting and de-setting times, increases savings potential when operating several machinesMore safety: automated sequences ensure reliable production processes

Requirements

- Hydraulic workpiece clamping (VN.9100610)

You might also be interested in

HELLER Newsletter

Register now!

The HELLER Newsletter provides you with information about all current topics concerning our company, our products and services as well as upcoming trade shows and events. Register now to make sure you never miss any news from the HELLER Group!