Harnessing AI for production

TEXT Gerda Kneifel (WGP) PHOTOS Daniel Ingold / IWF Berlin / IFW Hannover / IPK Berlin

Artificial intelligence (AI) is on everyone’s lips at the moment. As part of its Artificial Intelligence Strategy, the German government has promised to spend three billion Euros until 2025 to develop the brand AI – made in Germany, establishing the country as the world leader in this technology. Considering the investments and progress made in the US and increasingly also in China, this will not be an easy task. Yet, Germany has one crucial advantage: researchers working in close cooperation with manufacturing. “Artificial intelligence offers significant opportunities also in terms of production technology,” stresses Prof. Berend Denkena, President of WGP (German Academic Association for Production Technology) and Head of the Institute of Production Engineering and Machine Tools (IFW) at Leibniz University Hannover.

“As a research community we can and will promote this megatrend.”

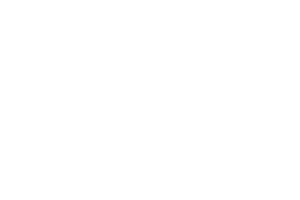

Various WGP institutes, e.g. in Aachen, Berlin, Erlangen, Karlsruhe and Stuttgart, are already conducting specific AI research in manufacturing. “With approximately 40 research institutes, WGP has a unique domain knowledge of production technology. With the knowledge gained from AI research, we now aim to create a basis for the strategic development of existing experiences, allowing to systematically harness the value creation potentials offered by AI in manufacturing that until now have only been exploited sporadically,” emphasises Prof. Jörg Krüger, Head of the Department of Industrial Automation Technology at the Institute for Machine Tools and Factory Management (IWF) at TU Berlin and Head of the Automation Technology division at the Fraunhofer Institute for Production Systems and Design Technology (IPK) in Berlin.

By early summer, the professors plan to draft a position paper which will, for the first time, outline the key questions and answers in relation to AI in production. “It will allow the German industry to increase the application of the new technology in the future and help them to generate an economic benefit from AI,” Krüger, who initiated the position paper, is convinced. Moreover, it is meant as a wake-up call to companies, prompting them to engage in the practical application of AI. Practical recommendations for action regarding the introduction of the technology aim to speed up the knowledge transfer. In Germany, it often takes years before research findings are implemented in business practice. With a rapidly developing technology like AI, the solutions implemented by companies would long be outdated by then.

“In order to find AI-based approaches to production technology-related problems, we first need to define and formulate the requirements on the AI systems,” Krüger describes the approach taken by WGP. “After all, an AI system does not know which data need to be captured at which point of the process chain to enable it to learn what has to be produced in which ways.” The WGP position paper’s task is to establish these requirements.

A 32 billion Euro sales increase thanks to AI

Already about 30 years ago, papers on production planning and machine diagnostics using artificial neural networks were published. Today, the volume of data available and the possibilities of data processing and storage are sufficient to tap into a number of new value creation potentials in production. “And the volume of data available will increase further in the future,” says Denkena.

Therefore, the WGP experts believe that AI will result in numerous innovations in production technology in the foreseeable future. The billions promised by the Federal Government and the universities’ investments into additional professorships show how great the potential of artificial intelligence is estimated to be. Moreover, the conclusion of the so-called PAiCE study commissioned by the Federal Ministry for Economic Affairs and Energy published in 2018 is that the technologies could be of major significance for the manufacturing sector. The Institute for Innovation and Technology (iit) in Berlin has calculated that the additional AI-induced growth in the coming four years will reach a volume of approx. 32 billion Euros. This corresponds to about a third of the overall growth of the sector within this period. The authors of the study recommend policy makers to promote AI technologies like machine learning and computer vision in a targeted manner. It will only be possible to achieve the massive growth projected when AI is used in a systematic manner. “Increasing added value through AI is not only possible with fully automated systems,” Krüger adds. “A significant increase in added value can also be achieved in partially automated systems or operator assistance systems. It offers distinct competitive advantages to the entire German industry.”

Perfecting production

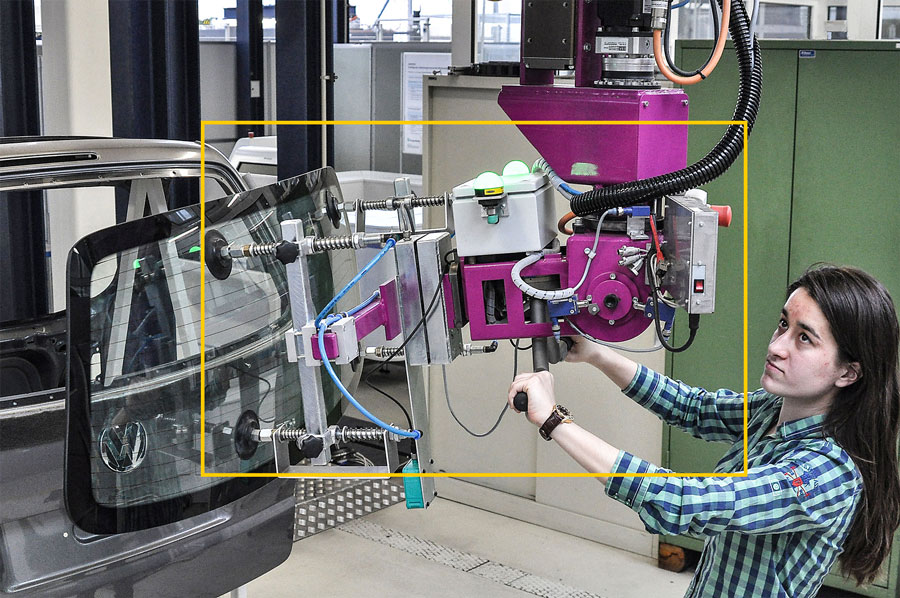

AI applications could be used for monitoring and maintenance of production systems, optimised resource and knowledge management, quality control, robotics and not least intelligent assistance systems. Experts believe that deep learning, a subfield of machine learning, holds exceptional potential for production technology. Already structured machine data from a range of different sensors, for example, could be linked to unstructured data such as images, videos or sound. Subsequently, machine learning algorithms could be used to identify specific patterns or correlations in the data. This again could help to detect anomalies at an early stage, preventing damage to the machine or even the overall system. The learning system, i.e. a self-monitoring plant, prevents production errors or even losses, reduces the maintenance or inspection effort and improves product quality and manufacturing efficiency.

AI also allows to achieve a significant increase in the precision and efficiency of individual machines. “An example from research shows that artificial intelligence can lead us to a better understanding of the foundations of cutting forces,” explains Krüger. “It helps us to further improve the long accepted and established cutting models. Metal-cutting machines will become more precise and more effective, because we know more about the counterforces involved in machining and are able to improve regulation of positioning accuracy,” Krüger says about a research project of his WGP colleague Prof. Christian Brecher of the WZL Laboratory for Machine Tools and Production Engineering of RWTH Aachen.

Moreover, production planning and control are important fields where AI systems could be used. In times of individual customer requirements and shorter lead times for order processing, automated determination of, for instance, processing sequences in flow production can provide higher added value. Prediction of material requirements or tools reduces waiting times whilst real-time decision support in case of unforeseen events increases production agility and reliability.

As companies are often short on personnel, AI-based services can be a lucrative new business model. The Israeli start-up 3D Signals, for instance, specialises in using microphones to monitor machines in order to identify unusual noise in real time. According to the German magazine WirtschaftsWoche, this helped a steel tube manufacturer to reduce downtimes, achieving savings of USD 180,000 within a two-month period. This shows that AI results in a win-win situation.

The German Academic Association for Production Technology is a consortium of leading German professors of production technology. The WGP stands for approximately 2,000 scientists of production technology and represents the interests of research and teaching in production technology vis à vis politicians, the public and representatives of economy. The aim is to raise the awareness of the significance of production and production science for society and Germany as a location and to take a stand concerning socially relevant future topics such as Industry 4.0, energy efficiency or 3D printing. Find out more about the WGP at https://wgp.de/en/.